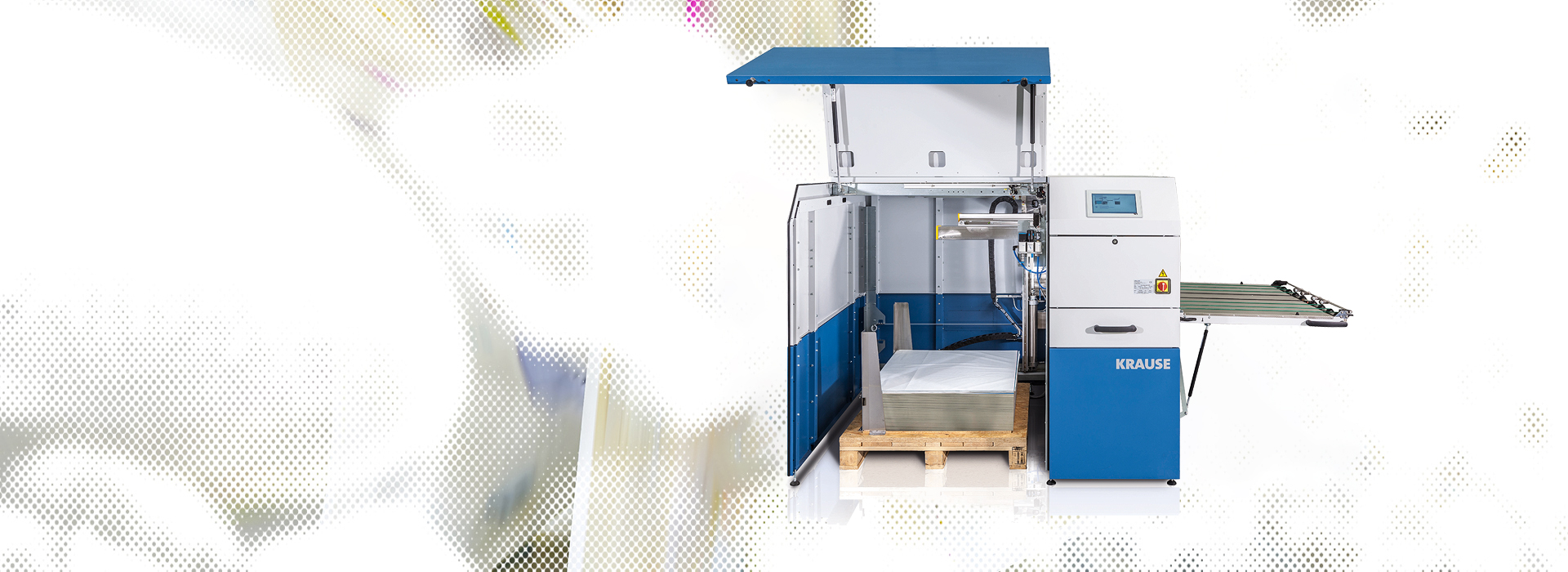

KRAUSE PowerLoader/APL for non-stop CTP production over several work shifts

Automate your CTP production to reduce unit costs. Eliminate many work steps and error sources to increase profitability. Direct loading from the pallet into the CTP platesetter without manual handling or lifting minimizes faulty plates plus waste and enables unmanned CTP production. The intuitive touch-panel operation and loading of the pallets can be done from the right or left side and ensures flexible space planning. The compact housing with a swiveling transfer table to the platesetter provides a safe working environment in prepress and allows easy access to the platesetter, e.g. for maintenance work.

PowerLoader/APL 8up 106 - 1,165 x 950 mm - 8 Pages - Print format 3B

POWERLOADER/APL 8UP 106 - SINGLE

- Laser markings enable easy alignment of the pallet in the loading area

- Automatic determination of the stack height after loading by starting the PowerLoader/APL

- Suction cup and gripper combination prevents damage to the surface of the printing plate

- Interleaving paper is removed during the loading process into an integrated transport container

- Ultrasonic sensor monitors plate transfer to increase process reliability

- Belt transport with plate alignment before the patesetter ensures perfect transfer

- Including communication interface to CTP platesetter for reliable production

Min. plate format:

605 x 745 mm

Max. plate format:

950 x 1,165 mm

Plate thickness:

0,2 bis 0,4 mm

Optional: 0,15 mm

Print format:

3B

POWERLOADER/APL 8UP 106 - MULTI

- Further automation options for the flexible processing of multiple plate formats

- Traversing suction and gripper systems for securely handling different printing plate formats

- Measurement and recognition of pallets, formats, stack heights and plate positions with several laser sensors

- Different plate formats can be loaded and processed from pallets (1 pallet loading bay)

- Possible integration of 1 or 2 cassettes for handling up to 3 online formats (by 2 cassettes with 80 plates each)

- Intelligent communication interface to the CTP platesetter for reliable production

Min. plate format:

605 x 745 mm

Max. plate format:

950 x 1,165 mm

Plate thickness:

0,2 bis 0,4 mm

Optional: 0,15 mm

Plate format:

3B

Smallest format in cassettes:

400 x 500 mm

POWERLOADER/APL 8UP 106 - MULTI WITH EXPANSION MODULE

- Capacity increase by an expansion module with a second loading bay for loading printing plates from pallets

- Flexible positioning of one or two pallets in the loading area (same or different formats)

- Automatic recognition of the pallet positions, no fixed location requirement necessary

- Possible integration of 1 or 2 cassettes for handling up to 4 online formats (by 2 cassettes with 80 plates each)

- Access with cassette system to a total of 4 printing plate formats, i.e. up to 2,560 printing plates as total capacity

- Intelligent communication interface to the CTP platesetter for reliable production

Min. plate format:

605 x 745 mm

Max. plate format:

950 x 1,165 mm

Plate thickness:

0,2 bis 0,4 mm

Optional: 0,15 mm

Print format:

3B

Smallest format in cassettes:

400 x 500 mm

PowerLoader/APL XL 150 – 1,524 x 1,276 mm - 16 Pages - Print format 6B

POWERLOADER/APL XL 150 - SINGLE

- Laser markings enable easy alignment of the pallet in the loading area

- Automatic determination of the stack height after loading by starting the PowerLoader/APL

- Suction cup and gripper combination prevents damage to the surface of the printing plate

- Interleaving paper is removed during the loading process into an integrated transport container

- Ultrasonic sensor monitors plate transfer to increase process reliability

- Belt transport with plate alignment before the platesetter ensures perfect transfer

- Accessibility to the following CTP platesetter is guaranteed by a swiveling transfer table

- Including communication interface to CTP platesetter for reliable production

Min. plate format:

605 x 745 mm

Max. plate format:

1.276 x 1.524 mm

Plate thickness:

0,3 bis 0,4 mm

Optional: 0,15 mm

Print format:

6B

Smallest format in cassettes:

400 x 500 mm

POWERLOADER/APL XL 150 - MULTI

- Further automation options for the flexible processing of multiple plate formats

- Traversing suction and gripper systems for securely handling different printing plate formats

- Measurement and detection of pallets, formats, stack heights and plate positions with multiple laser sensors.

- Different plate formats can be loaded and processed from pallets (1 pallet loading bay)

- Intelligent communication interface to the CTP platesetter for reliable production

Min. plate format:

605 x 745 mm

Max. plate format:

1.276 x 1.524 mm

Plate thickness:

0,3 bis 0,4 mm

Optional: bis 0,15 mm

Print format:

6B

POWERLOADER/APL XL 150 - MULTI WITH EXPANSION MODULE

- Capacity increase by an expansion module with a second loading bay for loading printing plates from pallets

- Flexible positioning of one or two pallets in the loading area (same or different formats)

- Automatic recognition of the pallet positions, no fixed location requirement necessary.

- Possible integration of 1 or 2 cassettes for handling up to 4 online formats (by 2 cassettes with 50-80 plates each)

- Access with cassette system to a total of 4 printing plate formats, i.e. up to 2,560 printing plates as total capacity

- Intelligent communication interface to the CTP platesetter for reliable production

Min. plate format:

605 x 745 mm

Max. plate format:

1,276 x 1,524 mm

Plate thickness:

0,3 bis 0,4 mm

Optional: bis 0,15 mm

Print format:

6B

Smallest format in cassettes:

400 x 500 mm

PowerLoader/APL XL 165 - 1,650 x 1,325 mm - 24 Pages - Print format 7B

POWERLOADER/APL XL 165 - SINGLE

- Laser markings enable easy alignment of the pallet in the loading area

- Automatic determination of the stack height after loading by starting the PowerLoader/APL

- Suction cup and gripper combination prevents damage to the surface of the printing plate

- Interleaving paper is removed during the loading process into an integrated transport container

- Ultrasonic sensor monitors plate transfer to increase process reliability

- Belt transport with plate alignment before the platesetter ensures perfect transfer

- Including communication interface to CTP platesetter for reliable production

Min. plate format:

605 x 745 mm

Max. plate format:

1,325 x 1,650 mm

Plate thickness:

0,3 bis 0,4 mm

Optional: bis 0,15 mm

Print format:

7B

POWERLOADER/APL XL 165 - MULTI

- Further automation options for the flexible processing of multiple plate formats

- Traversing suction and gripper systems for securely handling different printing plate formats

- Measurement and detection of pallets, formats, stack heights and plate positions with multiple laser sensors.

- Different plate formats can be loaded and processed from pallets (1 pallet loading bay)

- Intelligent communication interface to the CTP platesetter for reliable production

Min. plate format:

605 x 745 mm

Max. plate format:

1,325 x 1,650 mm

Plate thickness:

0,3 bis 0,4 mm

Optional: bis 0,15 mm

Print format:

7B

POWERLOADER/APL XL 165 - MULTI WITH EXPANSION MODULE

- Capacity increase by an expansion module with a second loading bay for loading printing plates from pallets

- Flexible positioning of one or two pallets in the loading area (same or different formats)

- Automatic recognition of the pallet positions, no fixed location requirement necessary.

- Possible integration of 1 or 2 cassettes for handling up to 4 online formats (by 2 cassettes with 50-80 plates each)

- Access with cassette system to a total of 4 printing plate formats, i.e. up to 2,560 printing plates as total capacity

- Intelligent communication interface to the CTP platesetter for reliable production

Min. plate format:

605 x 745 mm

Max. plate format:

1,325 x 1,650 mm

Plate thickness:

0,3 bis 0,4 mm

Optional: bis 0,15 mm

Print format:

7B

Smallest format in cassettes:

400 x 500 mm

PowerLoader/APL XL 190 - 1,860 x 1,425 mm - 32 Pages - Print format 8

POWERLOADER/APL XL 190 - SINGLE

- Laser markings enable easy alignment of the pallet in the loading area

- Automatic determination of the stack height after loading by starting the PowerLoader/APL

- Suction cup and gripper combination prevents damage to the surface of the printing plate

- Interleaving paper is removed during the loading process into an integrated transport container

- Ultrasonic sensor monitors plate transfer to increase process reliability

- Belt transport with plate alignment before the platesetter ensures perfect transfer

- Including communication interface to CTP platesetter for reliable production

Min. plate format:

605 x 745 mm

Max. plate format:

1,425 x 1,860 mm

Plate thickness:

0,3 bis 0,4 mm

Optional: bis 0,15 mm

Print format:

8

POWERLOADER/APL XL 190 - MULTI

- Further automation options for the flexible processing of multiple plate formats

- Traversing suction and gripper systems for securely handling different printing plate formats

- Measurement and recognition of pallets, formats, stack heights and plate positions with several laser sensors

- Different plate formats can be loaded and processed from pallets (1 pallet loading bay)

- Intelligent communication interface to the CTP platesetter for reliable production

Min. plate format:

605 x 745 mm

Max. plate format:

1,425 x 1,860 mm

Plate thickness:

0,3 bis 0,4 mm

Optional: bis 0,15 mm

Print format:

8

POWERLOADER/APL XL 190 - MULTI WITH EXPANSION MODULE

- Capacity increase by an expansion module with a second loading bay for loading printing plates from pallets

- Flexible positioning of one or two pallets in the loading area (same or different formats)

- Automatic recognition of the pallet positions, no fixed location requirement necessary.

- Possible integration of 1 or 2 cassettes for handling up to 4 online formats (by 2 cassettes with 35-80 plates each)

- Access with cassette system to a total of 4 printing plate formats, i.e. up to 2,560 printing plates as total capacity

- Intelligent communication interface to the CTP platesetter for reliable production

Min. plate format:

605 x 745 mm

Max. plate format:

1,425 x 1,860 mm

Plate thickness:

0,3 bis 0,4 mm

Optional: bis 0,15 mm

Print format:

8

Smallest format in cassettes:

400 x 500 mm

PowerLoader/APL XL 210 - 2,100 x 1,600 mm - 40 Pages - Print format 10

POWERLOADER/APL XL 210 - SINGLE

- Laser markings enable easy alignment of the pallet in the loading area

- Automatic determination of the stack height after loading by starting the PowerLoader/APL

- Suction cup and gripper combination prevents damage to the surface of the printing plate

- Interleaving paper is removed during the loading process into an integrated transport container

- Ultrasonic sensor monitors plate transfer to increase process reliability

- Belt transport with plate alignment before the platesetter ensures perfect transfer

- Including communication interface to CTP platesetter for reliable production

Min. plate format:

605 x 745 mm

Max. plate format:

1,600 x 2,100 mm

Plate thickness:

0,3 bis 0,4 mm

Optional: bis 0,15 mm

Print format:

10

POWERLOADER/APL XL 210 - MULTI

- Further automation options for the flexible processing of multiple plate formats

- Traversing suction and gripper systems for securely handling different printing plate formats

- Measurement and detection of pallets, formats, stack heights and plate positions with multiple laser sensors.

- Different panel formats can be loaded and processed from pallets (1 pallet loading bay)

- Intelligent communication interface to the CTP platesetter for reliable production

Min. plate format:

605 x 745 mm

Max. plate format:

1,600 x 2,100 mm

Plate thickness:

0,3 bis 0,4 mm

Optional: bis 0,15 mm

Print format:

10

POWERLOADER/APL XL 210 - MULTI WITH EXPANSION MODULE

- Capacity increase by an expansion module with a second loading bay for loading printing plates from pallets

- Flexible positioning of one or two pallets in the loading area (same or different formats)

- Automatic recognition of the pallet positions, no fixed location requirement necessary.

- Possible integration of 1 or 2 cassettes for handling up to 4 online formats (by 2 cassettes with 30 - 80 plates each)

- Access with cassette system to a total of 4 printing plate formats, i.e. up to 2,560 printing plates as total capacity

- Intelligent communication interface to the CTP platesetter for reliable production

Min. plate format:

605 x 745 mm

Max. plate format:

1,600 x 2,100 mm

Plate thickness:

0,3 bis 0,4 mm

Optional: bis 0,15 mm

Print format:

10

Smallest format in cassettes:

400 x 500 mm

KRAUSE Powerloader/APL loads printing plates automatically

The PowerLoader/APL automatically loads printing plates directly from pallets into the CTP platesetter - for efficient manless production and high cost savings.